|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

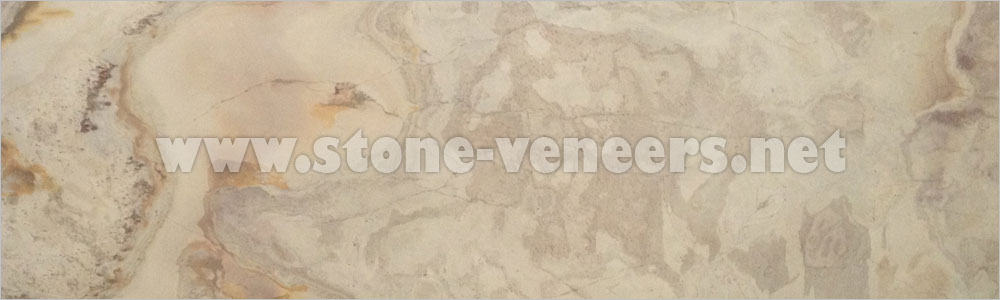

thin stone veneer installation – thin veneer installation guide, flexible thin stone veneer installation, natural stone veneer installation, how to install natural thin stone veneers, thin stone veneer installation details, how to apply stone veneer, natural stone veneer installation, how to hang stone veneer, real stone veneer installation, how to install rock veneer wall, install stone veneer interior wall, how to install stone facade at www.stone-veneers.net

thin stone veneer installation guide – installation, veneer, veneer installation, thin stone veneer installation guide, thin stone veneer, thin veneer install, rock siding, stone siding, natural thin veneer, stone installation, mortar formula, diamond blade, sealants, stone, veneer, natural stone veneer installation instructions, how to install stone veneer, natural stone veneers, thin stone veneer, stone veneers, veneer stone, stone veneer sheets, natural stone, stone veneer prices at www.stone-veneers.net

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||